Golf Shaft Hoop Strength

By Russ Ryden, A Golf Digest America’s 100 Best Clubfitter

Fit2Score, Dallas Fort Worth, Texas

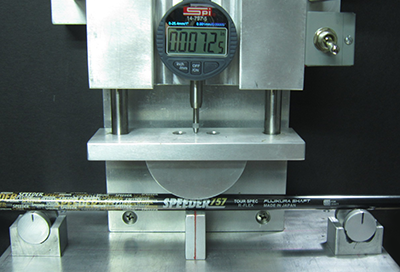

Hoop strength is discussed endlessly in the marketing of golf shafts but unlike other specifications, we are given no information about actual strength of one shaft vs another. After trying a few methods to measure hoop strength I arrived at the method shown to the right. It is a text book method, place a tube on a firm surface, drop a weight on it and see how much is deforms. I built a small block, slightly higher than the guides used for EI measuring and now have a tool for quantifying hoop strength. If this is a new term for you, follow this link to the AeroTech web site for a discussion. For those readers familiar with the term, you should note that the shaft in this image has some of the highest hoop strength I have yet to measure. It is a pull out that I played many, many years ago before I developed the current passion for understanding the golf shaft. A material called triax was wrapped into the shaft to add hoop strength and eliminate ovaling during the golf swing.

Hoop strength is discussed endlessly in the marketing of golf shafts but unlike other specifications, we are given no information about actual strength of one shaft vs another. After trying a few methods to measure hoop strength I arrived at the method shown to the right. It is a text book method, place a tube on a firm surface, drop a weight on it and see how much is deforms. I built a small block, slightly higher than the guides used for EI measuring and now have a tool for quantifying hoop strength. If this is a new term for you, follow this link to the AeroTech web site for a discussion. For those readers familiar with the term, you should note that the shaft in this image has some of the highest hoop strength I have yet to measure. It is a pull out that I played many, many years ago before I developed the current passion for understanding the golf shaft. A material called triax was wrapped into the shaft to add hoop strength and eliminate ovaling during the golf swing.

My first attempts to measure hoop strength were to look for ovaling. I clamped a shaft on a deflection device, measured the diameter at different points, bent it 5″ and measured again at those points. The differences were so small I decided there was more noise in the numbers I was reading than the variance I was trying to measure. I could not find .001 inch of difference. That might just make the rest of this article a waste of time, but if you are interested in the concept read on. With the device pictured above, the shaft is compressed with 11 kg and a change in diameter is apparent. The scale on the graphics is .002 inch increments.

Carbon Fiber Iron Shafts

Carbon Fiber Iron Shafts

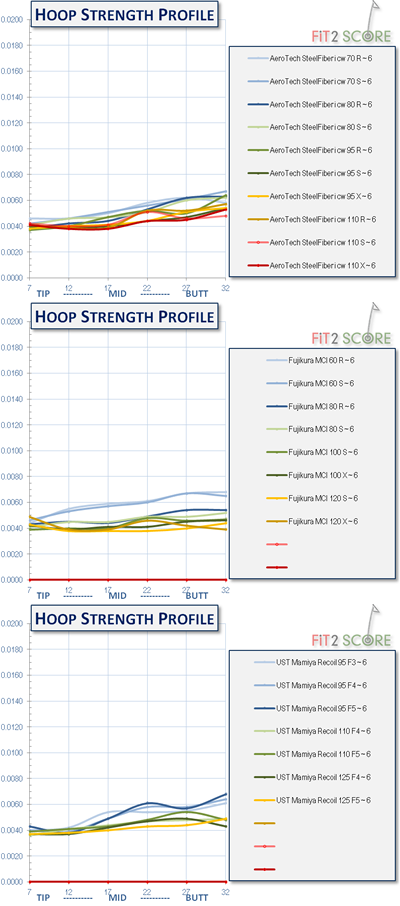

The focus of this article is iron shafts. I have not yet measured the shafts in my driver fitting system. Lets start by looking at my hoop strength measurements of some popular graphite six iron shafts that I fit with. Graphite wall thickness in heavy iron shafts creates high hoop strength. AeroTech maintains high hoop strength even as the shafts become lighter as a result of the filament winding process they uniquely use and the stainless steel wire wrapped around the shafts.

What you see looking at these charts is that heavy graphite shafts universally have high hoop strength. And even light weight graphite, the 70 gram AeroTech and the 60 gram Fujikura MCI, which also employs a metallic fiber in the shaft walls have high hoop strength.

As you look at these charts, take note that a low number, meaning very small deflection under load, indicates high hoop strength.

Steel Iron Shafts

Steel Iron Shafts

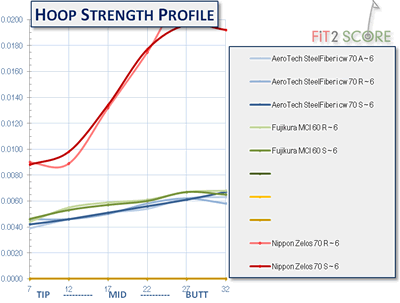

Now lets compare the hoop strength of some popular steel iron shafts. We immediately see less hoop strength in the butt sections of steel shafts. This is not limited to a particular brand, it is universally true.

What I found really interesting was that the hoop strength profiles were the same shape as the EI profiles. The stiffness of a steel shaft is determined by the wall thickness and the diameter of the shaft.

The material, a steel alloy, is consistent through out the shaft. In contrast, carbon fiber composite shafts material properties can change through out the shaft.

But wait a minute. I looked at both the Modus3 Tour 120 and the Modus3 Tour 130. Both have very different EI profiles. Yet, the hoop strength profiles are similar. Nippon steel has some interesting technology in their production lines.

Light Weight Steel

Light Weight Steel

One final image, a comparison of Ultra Light Steel to high quality light weight carbon fiber iron shafts. Do not come away with the impression that all light weight graphite shafts are going to have hoop strength like the high end shafts you see here. They do not.

What does it all mean to your game. I cannot say with certainty at this point how hoop strength manifests itself in shaft stability and dispersion control. Or if it can create kick velocity. Nor can I give you direction on what amount of hoop strength is appropriate for your loading patterns. You are looking at these charts within a week of creation of this addition to my knowledge base. But, at least now we have a measurement platform to begin the discovery process.