There are two types of iron shafts, factory trimmed sets and parallel shafts. The unitized parallel tip shaft was introduced by True Temper is the early 70’s. That was long before my involvement with golf gear so I will not make any attempt to discuss the history. This article will start with a brief explanation of the two shaft types and then discuss what I see using EI measurements. If you are a golfer and not a club builder I will lay out some background knowledge to give you a fundamental understanding of iron shafts. If you are a club builder and have not seen one of my presentations about parallel shafts, this article presents a unique understanding of the properties of parallel shaft sets.

Factory Trimmed Iron Shaft Sets

Sets of shafts are available cut to length from the shaft manufacturer. The shafts in the set are labeled with the iron they are designed for, 3, 4, 5, etc. The set is trimmed in 1/2 increments. The 4i shafts is 1/2 inch shorter than the 3i shaft, the 5i is 1/2 shorter than the 4i and so on. This photo is of such a set, 4i – wedge.

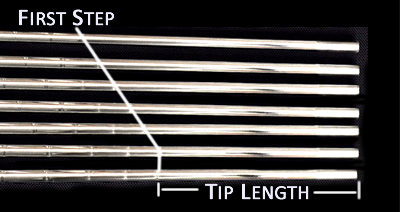

In a set like this, the distance between the tip and the first step is where you will see the 1/2 inch increment. The longer iron shafts have longer tips, making them ‘softer’ than the shorter iron shafts with stiffer tips. This is to synchronize stiffness in the set. Long iron heads are lighter than short iron heads. The shorter tips match with the heavier heads, increasing tip stiffness as the weight of the heads get heavier.

In a set like this, the distance between the tip and the first step is where you will see the 1/2 inch increment. The longer iron shafts have longer tips, making them ‘softer’ than the shorter iron shafts with stiffer tips. This is to synchronize stiffness in the set. Long iron heads are lighter than short iron heads. The shorter tips match with the heavier heads, increasing tip stiffness as the weight of the heads get heavier.

Most factory trimmed sets are called Constant Weight Tapers. The tips are .355″ diameter and are tapered to fit into tapered iron hosels. This taper makes trimming the tips prohibitive, although it is possible to make small tip trim adjustments on taper tip shafts. Constant weight refers to each shaft in the set being approximately the same weight even though they are different lengths. This is a big issue in creating overall shaft balance in either swing weight or MOI matched sets of irons.

Not all factory trimmed iron shaft sets are tapered, some are parallel. Nippon offers the entire NS Pro series in either .355 taper tips or .370 parallel tips.

Not all factory trimmed iron sets are constant weight. The True Temper XP and Dynamic Gold Progressive sets get lighter as they get shorter.

Parallel Iron Shafts

Parallel Iron shafts come from the factory at a single length. This is a set of KBS Tour C Taper Lite Parallel Shafts. The word Taper is not exactly correct, like all parallel shafts the tips are .370. These shafts are designed to be tip cut 1/2 inch per shaft, then butt cut to length.

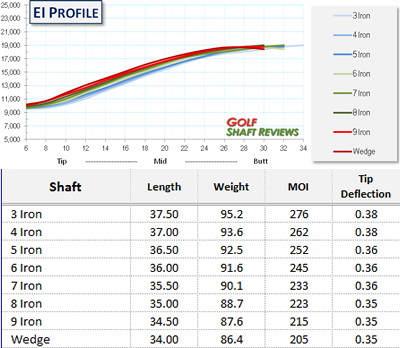

This creates a set as shown to the right, illustrated from the Fit2Score set documentation software. The raw shaft weighed 106 grams. The first cut brings it to 95 grams in a 3 iron and each successive cut of 1/2 inch from the tip reduces the weight about 1.3 grams with the wedge shaft weighing 86.4 grams.

This creates a set as shown to the right, illustrated from the Fit2Score set documentation software. The raw shaft weighed 106 grams. The first cut brings it to 95 grams in a 3 iron and each successive cut of 1/2 inch from the tip reduces the weight about 1.3 grams with the wedge shaft weighing 86.4 grams.

Creating MOI or Swing Weight matched sets requires additional weighting in the head to get the desired dynamic weight. The dynamic weight of the parallel shafts in this example drop 25% from the 3 iron to the wedge. In a set of constant weight shafts this loss would be half of that.

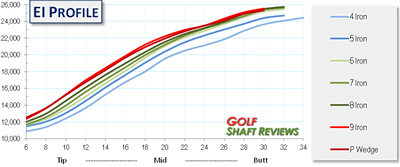

Lets take a look at the design of a typical parallel shaft. They are designed to be cut from the tip to create different lengths. In doing so, the stiffness is increased by moving the mid section of the shaft closer to the tip. The tip is the softest part of the shaft. As it is cut away, the shaft becomes stiffer. The mid section, where the shaft loses stiffness slides closer to the tip.

Lets take a look at the design of a typical parallel shaft. They are designed to be cut from the tip to create different lengths. In doing so, the stiffness is increased by moving the mid section of the shaft closer to the tip. The tip is the softest part of the shaft. As it is cut away, the shaft becomes stiffer. The mid section, where the shaft loses stiffness slides closer to the tip.

But look closely, what else are we seeing. The bend profile of the shaft is changing. We are creating a flighted shaft set. The longer shafts will have a propensity to launch higher while the shorter shafts will launch lower. That is the essence of what is called a flighted or a progressive launch set of shafts.

Compare the profiles of this set of KBS Tour Constant Weight Taper shafts to the set of the parallel shafts above. The constant weight set ascends in stiffness uniformly through out the set. The mid to tip change in stiffness is uniform through out the set.

Compare the profiles of this set of KBS Tour Constant Weight Taper shafts to the set of the parallel shafts above. The constant weight set ascends in stiffness uniformly through out the set. The mid to tip change in stiffness is uniform through out the set.

Viewed from this perspective, sets build from parallel shafts are fundamentally different from constant weigh sets. The change in dynamic weight is not entirely a negative, it must be balanced against the desire to create a flighted set of irons. This brings to mind a story told to me by a PGA Tour shaft company rep many years ago. I was told Greg Norman changed from Royal Precision Rifles, parallels, to another brand of constant weight shafts. He went without a win for a long time. The rep had his caddy recommend that he try going back to the Rifles. He did and went on a streak, winning that week and finishing high for the remainder of the year. That story never made much sense to me at the time. Now, having looked closely at parallel shafts as I rewrite the Fit2Score EI profiling software, the AhHa moment arrived. The typical parallel set is flighted! It is the nature of the beast.

Early in the article I said, “Not all factory trimmed iron sets are constant weight. The True Temper XP and Dynamic Gold Progressive sets get lighter as they get shorter.” The Dynamic Gold Progressive looks to me like the profile of a parallel set. Look at the loss of weight in the set. The True Temper XP115 occupies some middle ground, not as much loss of weight, but certainly to some degree showing flighted launch.

Early in the article I said, “Not all factory trimmed iron sets are constant weight. The True Temper XP and Dynamic Gold Progressive sets get lighter as they get shorter.” The Dynamic Gold Progressive looks to me like the profile of a parallel set. Look at the loss of weight in the set. The True Temper XP115 occupies some middle ground, not as much loss of weight, but certainly to some degree showing flighted launch.

Future reviews of iron shafts will not only show the profiles of the 6 iron as I have in the past. The set make ups will be included.