Mitsubishi OT Iron Shaft

By Russ Ryden, A Golf Digest America’s 100 Best Clubfitter

Fit2Score, Dallas Fort Worth, Texas

It is not often that we get to see truly new technology in the golf shaft business. The Mistubishi OTi series is something in my experience is truly new.

Lets start with the prepreg. Prepreg is typically the sheets of material, made of carbon fiber threads and resin, that are wrapped around a mandrel. The ‘sandwich’ is then wrapped with a retaining material, hung on a rack and baked. The cooked shaft is then unwrapped, the mandrel is pulled out and the process continues through sanding, trimming and finishing. The only exception I know of is AeroTech’s filament winding process.

Lets start with the prepreg. Prepreg is typically the sheets of material, made of carbon fiber threads and resin, that are wrapped around a mandrel. The ‘sandwich’ is then wrapped with a retaining material, hung on a rack and baked. The cooked shaft is then unwrapped, the mandrel is pulled out and the process continues through sanding, trimming and finishing. The only exception I know of is AeroTech’s filament winding process.

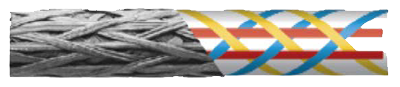

Mitsubishi Rayon has given us a new technology, braiding. it starts with a new form of prepreg they call Tow. The carbon fibers are arranged in bundles, the way a steel cable is made. The bundles are impregnated with resin and then woven into a braid. That braid bundle is then woven onto the mandrel. Yes, woven, I check on that. No spine. And the highest hoop strength I have seen on a graphite shaft. And given that heavy graphite hoop strength is lower than steel, the absolute lowest hoop strength in the business. The torque of all the models is about the same, 2.5 at the butt, 2.0 at the tip. Not as low as the same weight steel, but in the same range as other premium graphite iron shafts.

Mitsubishi Rayon has given us a new technology, braiding. it starts with a new form of prepreg they call Tow. The carbon fibers are arranged in bundles, the way a steel cable is made. The bundles are impregnated with resin and then woven into a braid. That braid bundle is then woven onto the mandrel. Yes, woven, I check on that. No spine. And the highest hoop strength I have seen on a graphite shaft. And given that heavy graphite hoop strength is lower than steel, the absolute lowest hoop strength in the business. The torque of all the models is about the same, 2.5 at the butt, 2.0 at the tip. Not as low as the same weight steel, but in the same range as other premium graphite iron shafts.

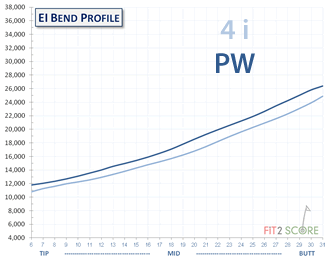

Radial consistency is off the charts, average 99.9% with a 0.1% standard deviation. I never thought I would see those kind of numbers. Shaft manufacturing technology is improving and new standards are being written. You can absolutely disregard shaft alignment with the Mitsubishi OT iron shaft. They are as round as I can measure round. If you are familiar with past Mitsubishi iron profiles, you will know these shafts. The Fubuki AXi family, one of my long time favorites no longer available is very close to this design. A Blue board like profile, a bit soft in the middle by design.

These are parallel design. I virtually trimmed the review profiles and found the design creates sets with very little flighting. This seems to be a trend in some of the recent parallel graphite shaft designs.

These are parallel design. I virtually trimmed the review profiles and found the design creates sets with very little flighting. This seems to be a trend in some of the recent parallel graphite shaft designs.

A benefit of carbon fiber parallel shafts is consistency within the set. Constant weigh shafts require multiple mandrels and multiple designs within the set to create consistency from shaft to shaft. They are essentially 8 different shafts and require both design and manufacturing integrity to deliver consistency within a set. This is not so with parallels. One mandrel, one manufacturing procedure. With reasonable attention to manufacturing processing it is easier to deliver consistent sets. Yes, there will be some weight loss and balance change as the shafts get shorter. But, one has to balance that against set consistency. And on that issue, from my recent observations, the jury is still out.

For those fitters and players that were familiar with the Fubuki AXi, the replacement has arrived. Go to the Mitsubishi OT expecting the same flighting. The review samples are getting tipped and heading to the range for feel testing.