Fujikura Speeder Evolution Driver Shaft

Russ Ryden, Golf Digest America’s 100 Best Clubfitter

Fit2Score, Dallas Fort Worth, Texas

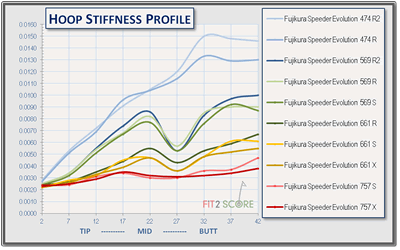

The Fujikura Speeder 757 was my introduction to premium driver shafts many years ago. The Speeder brand name disappeared for many years. It was brought back a few years ago as the Motore Speeder, a complex matrix of 26 shafts, featuring 3 launch designs, each in an array of weight and flex. In late 2013 the Speeder brand was reintroduced with 8 shafts, numbered like the original Speeder. The Fujikura Speeder Evolution came to the golfing public in 2015. It is designed to handle the heavier driver heads we are now seeing. As you can see in this illustration, the tip is stiffer and there is a tip-mid stiffness adjustment as part of the design update.

The Fujikura Speeder 757 was my introduction to premium driver shafts many years ago. The Speeder brand name disappeared for many years. It was brought back a few years ago as the Motore Speeder, a complex matrix of 26 shafts, featuring 3 launch designs, each in an array of weight and flex. In late 2013 the Speeder brand was reintroduced with 8 shafts, numbered like the original Speeder. The Fujikura Speeder Evolution came to the golfing public in 2015. It is designed to handle the heavier driver heads we are now seeing. As you can see in this illustration, the tip is stiffer and there is a tip-mid stiffness adjustment as part of the design update.

Like all of the Speeder models from Fujikura the profiles are consistent throughout the model. As the weight increases so does the stiffness. The Speeder 474 R2 weighs 48 grams uncut. The weights and stiffness ascend from a 4″ deflection yielding 5.8 lbs for the 474R2, and 8.6 lbs for the 79 gram 757X. The raw shafts are 47″ long, not the typical 46″.

Lets take a look at the profiles, they vary by model:

The technical discussion and measurements are available only to registered readers

The Speeder Evolution is a classical design, mid soft in relation to a stiffer butt and tip.This design is a good fit for the majority of golfers. We can see the research done on the 3D ENSO system shaping the butt to create softer handles.

An interesting aspect of these shafts stood out during hoop stiffness testing. A significant ‘bump’ of hoop stiffness in the high midsection of the shaft. If you look at the EI curves you will see this is where the shaft is quickly descending in stiffness. At that point, an ultra high modulus hoop ply was added to preserve shaft stability.

An interesting aspect of these shafts stood out during hoop stiffness testing. A significant ‘bump’ of hoop stiffness in the high midsection of the shaft. If you look at the EI curves you will see this is where the shaft is quickly descending in stiffness. At that point, an ultra high modulus hoop ply was added to preserve shaft stability.

Hoop stiffness is a function of wall thickness. near the tip, where the wall of the shaft are thick, the hoop stiffness is high. This graphic shows hoop deflection measurements. The less deflection, the stiffer that area of the shaft is. This is hoop stiffness, not bend stiffness. Hoop stiffness relates to the shaft ovalizing. The lower the number, the less oval deformation I measured. So, the dips you see are increases in hoop stiffness. The design objective in the Fujikura Speeder Evolution is to create shaft stability, and hence feel, in the section of the shaft where to majority of the load related bending occurs. What you see is the result of engineered wall thickness and high density pitch fiber pregreg in the hoop orientation, stabilizing the mid/butt region of the shaft.

An interesting discussion on another golf forum contained this comment, “This is the answer to all the “profile is profile” theorists – whose claim is that if I match bend pattern, weight, balance point and frequency then my $12 shaft is the same as your $175 shaft. Torque progression and distribution aren’t as handy to quantify but are essential elements in any high-performance design, and aren’t to be had for peanuts.” We see in the Speeder Evolution design is what this writer was talking about. A highly evolved design using the latest high density fibers, fiber orientation and wall thickness control to create a performance enhancing golf shaft.

---