EvenFlow Riptide MX Golf Shaft Review

By Russ Ryden, Fit2Score, A Dallas Fort Worth Club Fitter & Club Maker

By Russ Ryden, Fit2Score, A Dallas Fort Worth Club Fitter & Club Maker

The Highlands Performance Golf Center, Carrollton Texas

Golf Digest Certified America’s 100 Best Club Fitter

![]()

There was a sense of familiarity as the first EI Flex Distribution Graph formed as I measured the Riptide MX. I have seen this profile before, in fact it is an archetypical design. Successful on tour after a very, very long time, the profile is available from several shaft companies.

To continue reading this section of the review, you must be registered at a higher level membership.

Russ

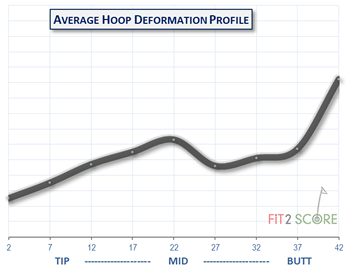

I have seen many shafts over the years with a woven material placed in the butt of shafts. This is as an indication that shaft manufactures recognize the thin walls near the but of the shaft deform and oval under load. The ovaling of the shaft in this area can contribute to shot dispersion. The woven Kevlar® material use by Mitsubishi is the only material I have measured to date where I can see a measurable effect. Hoop deformation significantly dips in this section of the shaft. Reduced hoop deformation in the 1K weave is the same as the CK weave. Mitsubishi tells us the 1K material transmits more feel.

I have seen many shafts over the years with a woven material placed in the butt of shafts. This is as an indication that shaft manufactures recognize the thin walls near the but of the shaft deform and oval under load. The ovaling of the shaft in this area can contribute to shot dispersion. The woven Kevlar® material use by Mitsubishi is the only material I have measured to date where I can see a measurable effect. Hoop deformation significantly dips in this section of the shaft. Reduced hoop deformation in the 1K weave is the same as the CK weave. Mitsubishi tells us the 1K material transmits more feel.